LOVATO Electric and the production of electronic devices: LOVATO Electronic is born

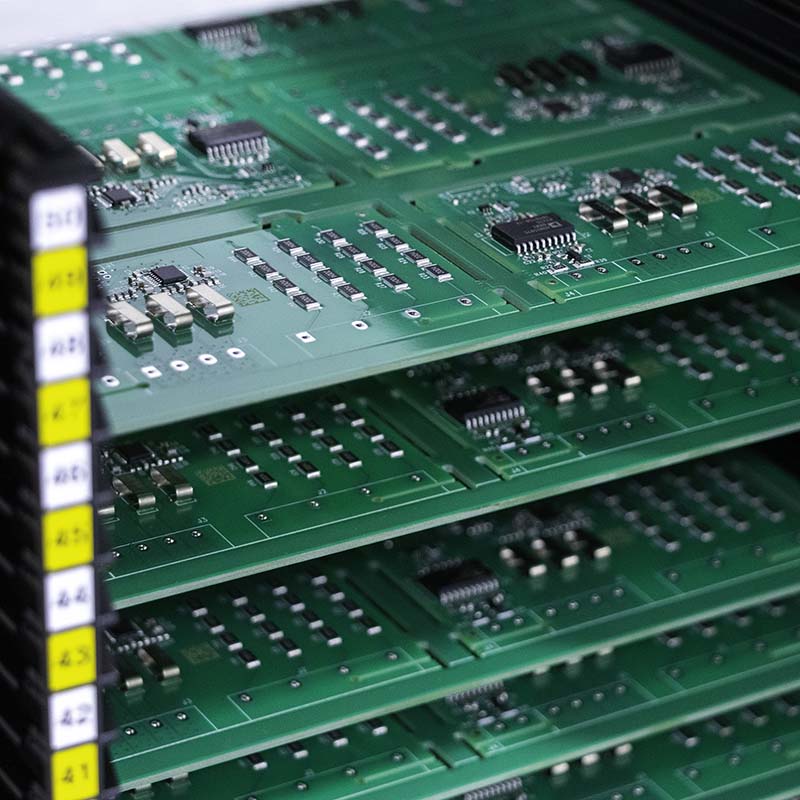

LOVATO Electric proudly announces the opening of a state-of-the-art department dedicated to the production of electronic boards (SMT) at its headquarters in Bergamo.

A significant step forward in the company’s expertise in the design and production of electronic devices.

The sale of electronic products, particularly related to machinery automation, e-mobility, and photovoltaics, has become increasingly important for the company in recent years. LOVATO Electric’s first electronic product, a star-delta timer, dates back to 1976.

This new department has been established to offer a series of advantages to the company’s customers. The know-how related to the electronic production process will be significantly improved, allowing meticulous optimization of the process, higher product quality, and faster delivery times.

The new department covers an Electrostatic Protected Area (EPA) of 300 square meters and consists of two smart warehouses with a capacity of over 2,500 coils, a static warehouse with humidity control for PCB (printed circuit board) and sensitive components, an assembly line for boards equipped with Pick & Place Fuji, and equipped with 3D inspection machines for solder paste and boards after reflow inspection.

The department is also equipped with an ICT (in-circuit test) testing station with 6 movable probes and a system for complete traceability of electronic components.

To support this initiative, LOVATO Electric has also hired new qualified personnel.

“Our Gorle headquarters,” says Massimiliano Cacciavillani, CEO of the company, “is becoming increasingly a center of technology. Our goal is to further increase the company’s innovation capacity and be quick and responsive to meet customer needs.”